The Harmful Effects of Arsenic In Water

Arsenic is a natural component from the Earth, distributed evenly in the land, air and water. Arsenic in its inorganic form is extremely dangerous for human health. When drinking water from an underground source is exposed to arsenic content for the long term, it causes skin lesions, gangrene and health hazards like cancer. Experts have also associated it with diabetes and cardiovascular disorders. In young children, too much arsenic in water consumption impacts cognitive development and causes death.

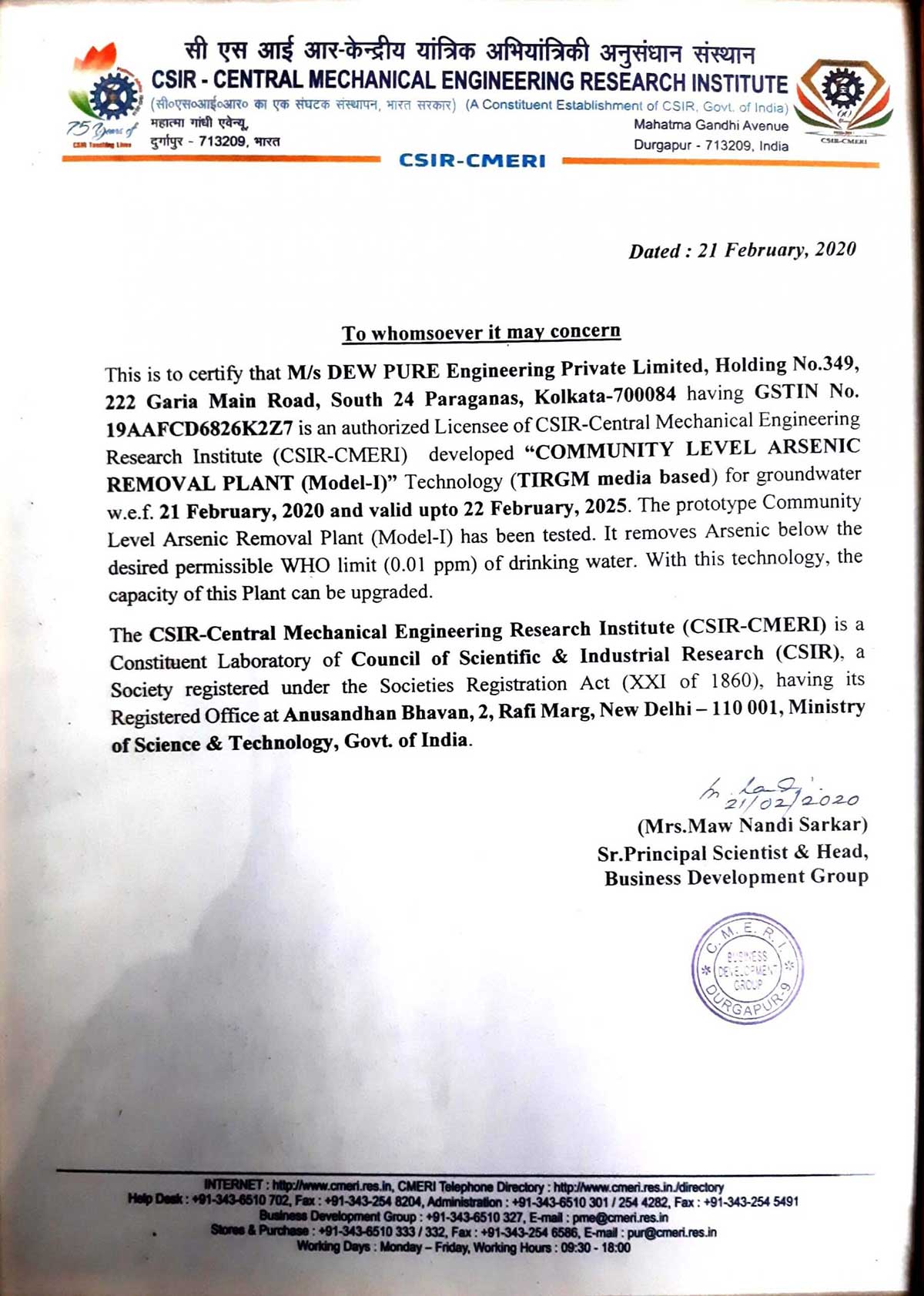

This is where the arsenic removal water plants undertake preventive measures to minimise arsenic exposure to drinking water and ensures a continued supply of safe drinking water for all. The filtration system undertaken in these plants is highly effective in purifying water by removing minute particles and dissolved impurities so that people can consume it safely.

Advantages of Installing Arsenic Removal Water Plants

- You can get instant pure water

- There are no major changes in its natural taste

- You can quickly get rid of iron and turbidity from the water

- Get safe drinking water from the main water supply

- Prevent discoloration of the clothes

- There are no recurring additional expenses at all

- Prevent excessive hair loss or sticky hair

- Keep your Non-electrical devices safe with less maintenance

- No problem of iron deposits, clogging or choking

Treatment Methods Used in Arsenic Removal Plant

In those areas where water for drinking is unsafe for consumption because of high arsenic levels, the arsenic removal water plant becomes a safe source to reduce short term water consumption crisis. The working operatives undergo different treatment methods to lower arsenic levels –

Oxidation

In those areas where water for drinking is unsafe for consumption because of high arsenic levels, the arsenic removal water plant becomes a safe source to reduce short term water consumption crisis. The working operatives undergo different treatment methods to lower arsenic levels –

Oxidation

This technique effectively removes the arsenic in pentavalent form or (As(V), arsenate). As it is less mobile compared to arsenite, it starts co-precipitating with the metallic cations and gets absorbed into solid surfaces. These treatment plants do a the step of oxidation for the conversion of arsenite to form arsenate. They oxidise it with these elements - oxygen (O2), permanganate (HMnO4), hypochlorite (HClO), hydrogen peroxide (H2O2). Some opt for air oxidation, but the process is slow.

In-situ oxidation in the Aquifier of iron and arsenic

In this process, the operatives extract the water from a kind of tube well, allowing it to oxygenate in the air alongside atmospheric oxygen. It then runs into the aquifier which is iron and arsenic-contaminated via that similar tube well. Gradually a firm coating of iron hydroxide develops along the well strainer on the sand grains. Finally, this water becomes safe for consumption with lowered arsenic levels.

Coagulation with lime

You can treat water by adding quick lime, CaO, or hydrated lime, Ca(OH)2 to remove arsenic content. This lime coagulation method is similar to coagulation with a metal salt. The precipitated form of calcium hydroxide or Ca(OH)2 functions as an absorbing flocculent for arsenic. The excess lime does not dissolve; instead, it remains caught as a coagulant aid, which is later removed through filtration and sedimentation.

Ion Exchange

The technique of Ion exchange is similar to activated alumina. Only the medium is synthetic resin with a better-defined capacity of ion exchange. The basis of the synthetic resin is a cross-linking polymer skeleton known as the matrix.

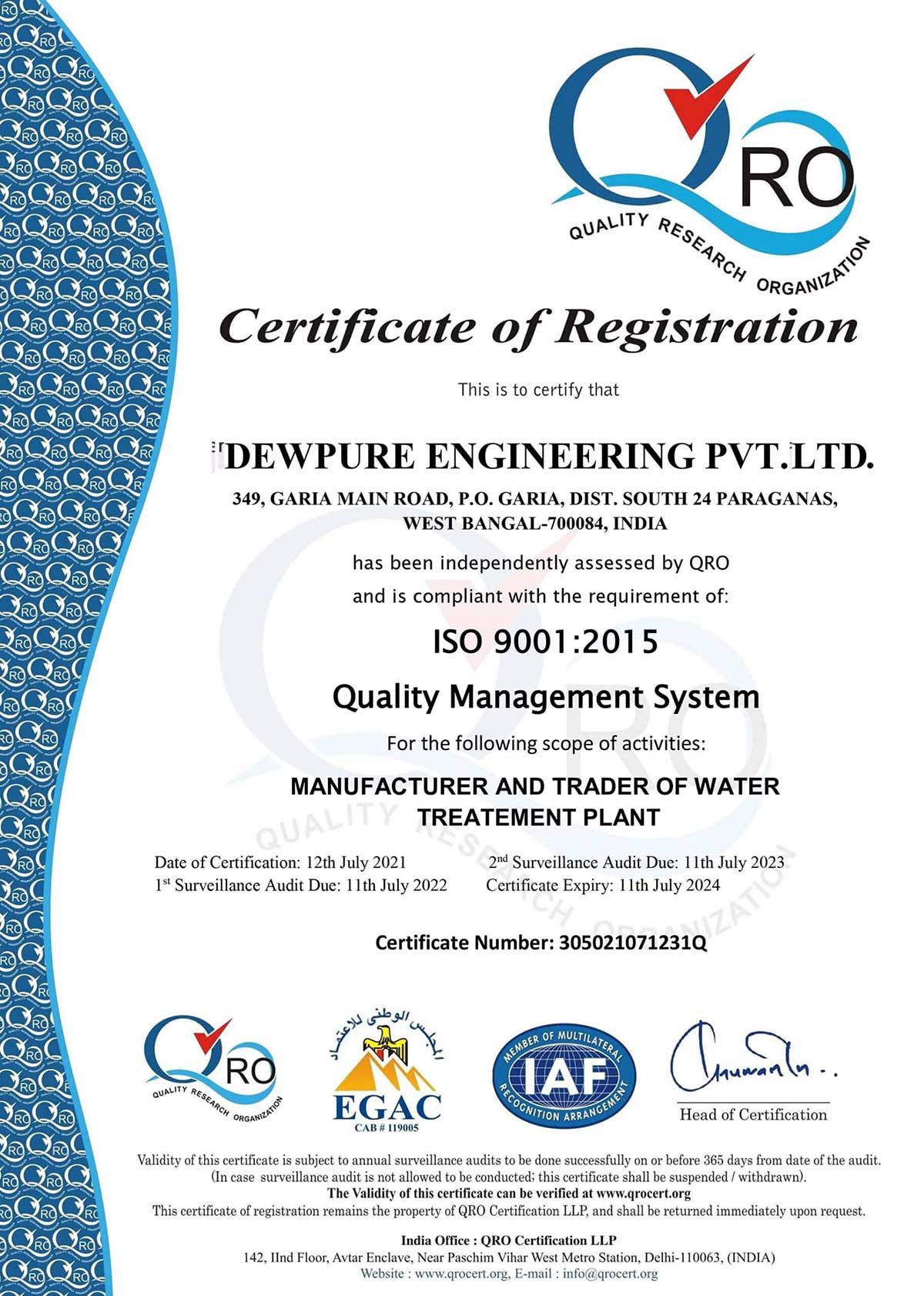

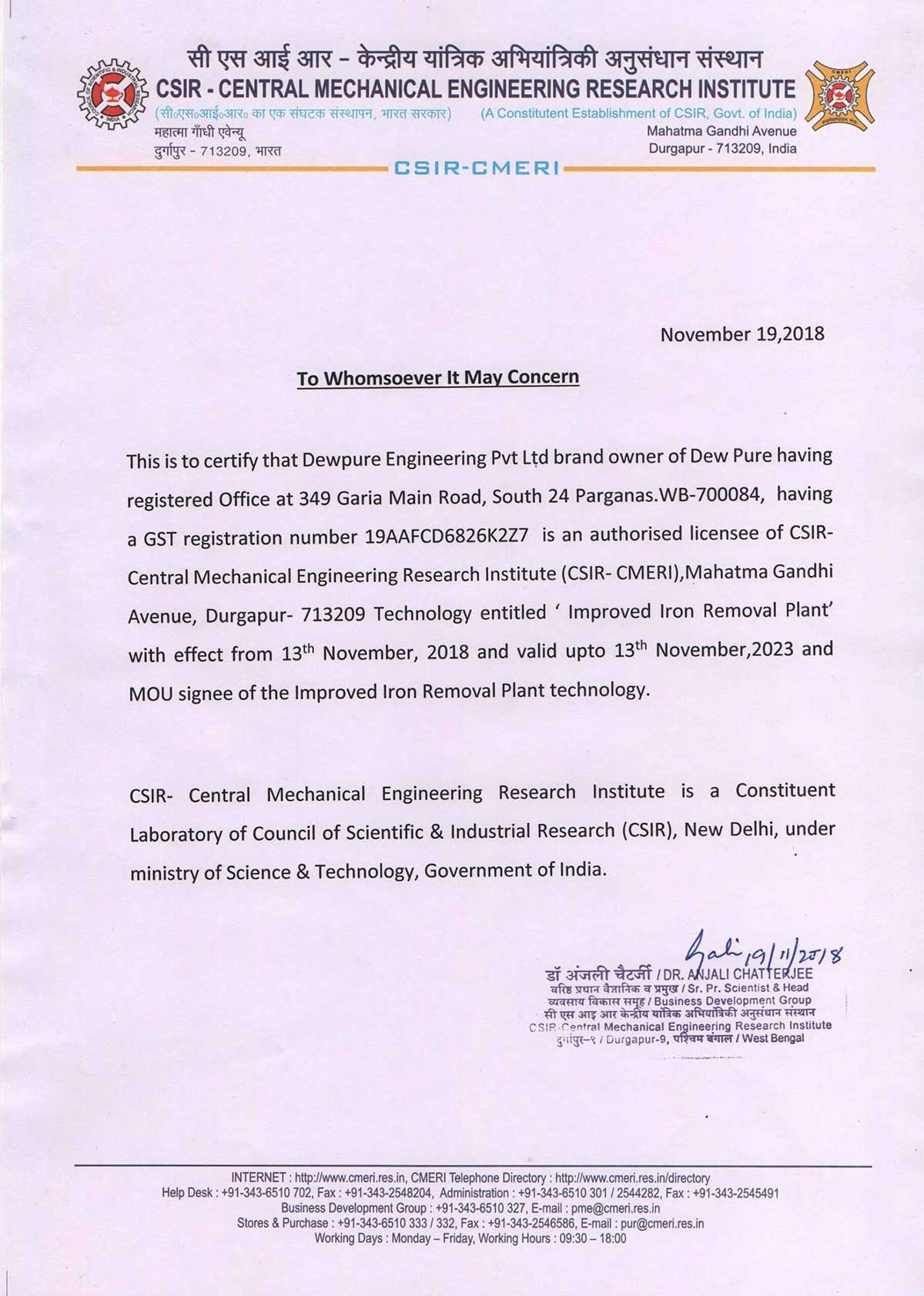

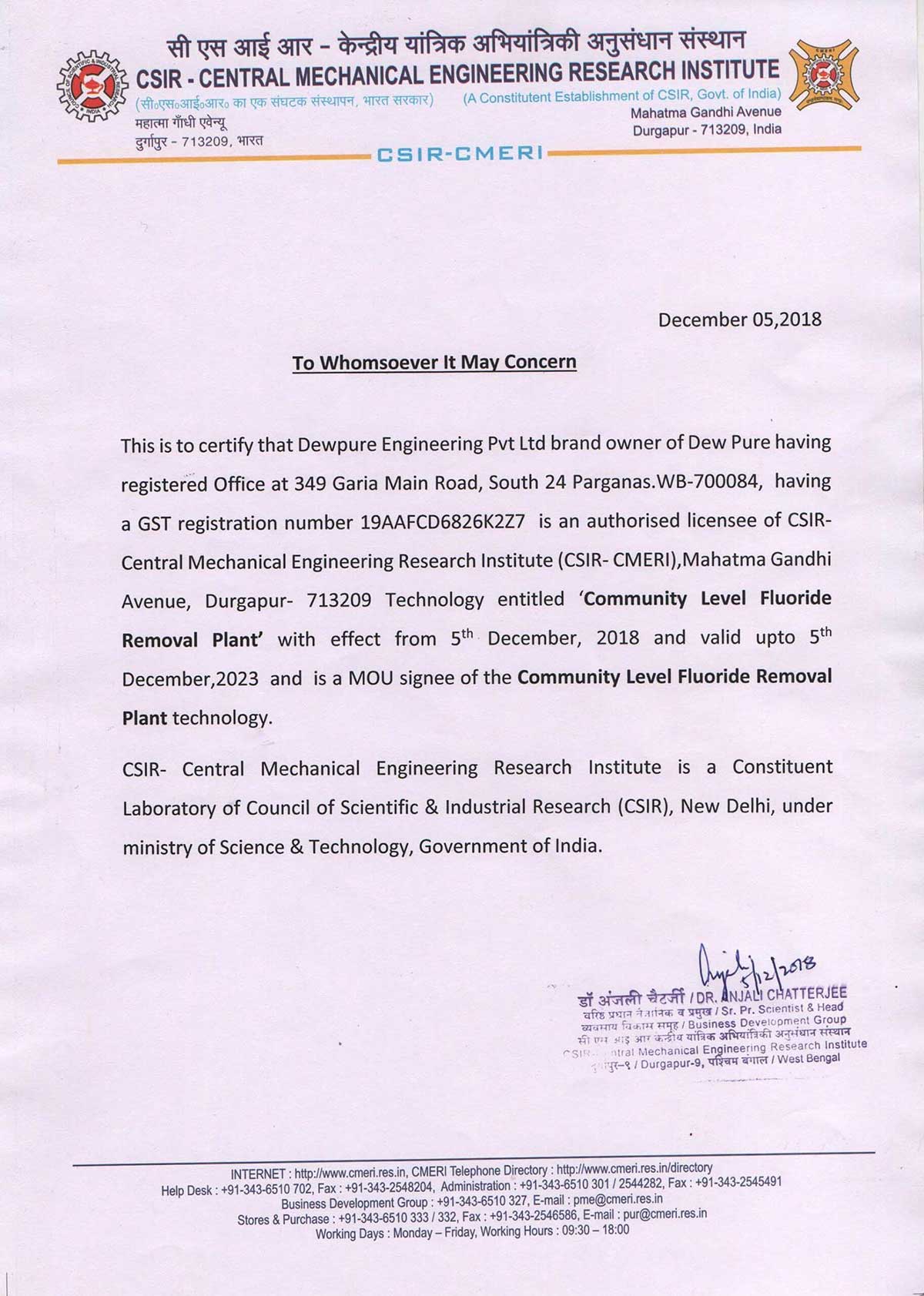

For further information about arsenic removal plants and removal processes, consult Dewpure.