Plant monitoring

Regular monitoring of RO plants helps in detecting the reasons for failure and does what is necessary to mitigate the effects of such failure. Always follow the monitoring procedures properly to avoid any ill functioning of the plant. Some of the most crucial factors that might lead to poor performance of the plant are:

- Choosing an unsuitable cartridge filter

- Overdose of pre-treatment flocculants

- Choosing incorrect inhibitor or failed acid dosing

- Presence of residual chlorine in the feed stream

- Organic loading or high iron

- High microbiological count

- Carbon fines or colloidal breakthrough

These issues can lead to massive membrane fouling, the most common performance problem. And the possible effects of it are poor salt rejection, decreased membrane productivity and increased differential pressure on the membranes.

Precise data collection and monitoring

Thorough plant monitoring can help you prevent system failures that may happen for different types of reasons. Some major factors affecting the performance of RO membrane are:

- System operating parameters

- Condition of raw water supply

- Degree of plant monitoring and maintenance

- Efficiency of pre-treatment methods

- Receptiveness of plant operators to crucial performance shifts

- Degree and rate of fouling

Regular data collection and plotting are essential to monitor the membrane performance based on some parameters like temperature, pH, pressure drop, etc. Modern innovations in the scale inhibition technology have made it easier to observe and optimize treatment chemicals with the help of traced products.

Proper maintenance is essential to ensure optimum performance of a Reverse Osmosis Plant. As it is a huge investment proposition, you must follow the guidelines and ensure that it operates smoothly at all times.

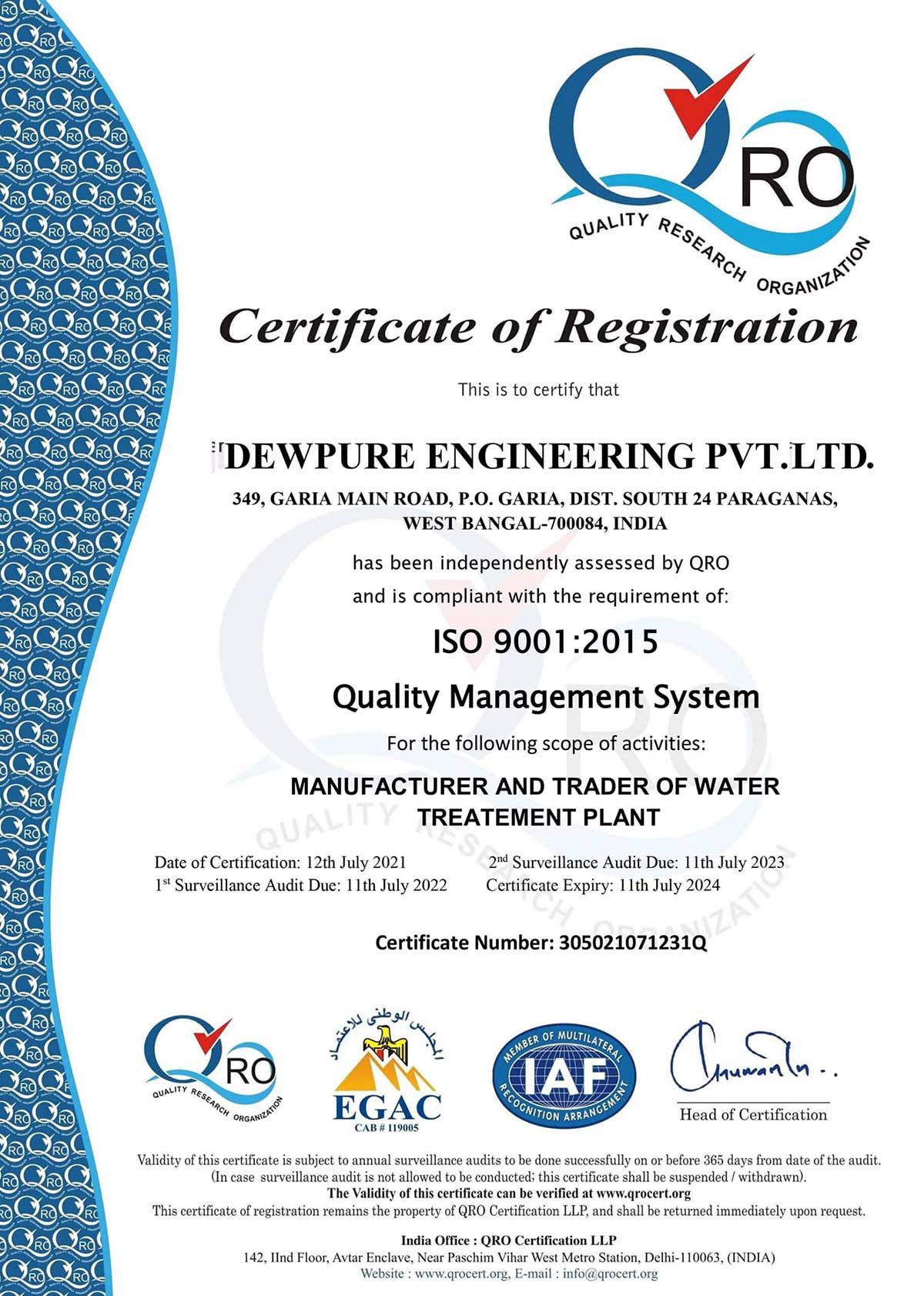

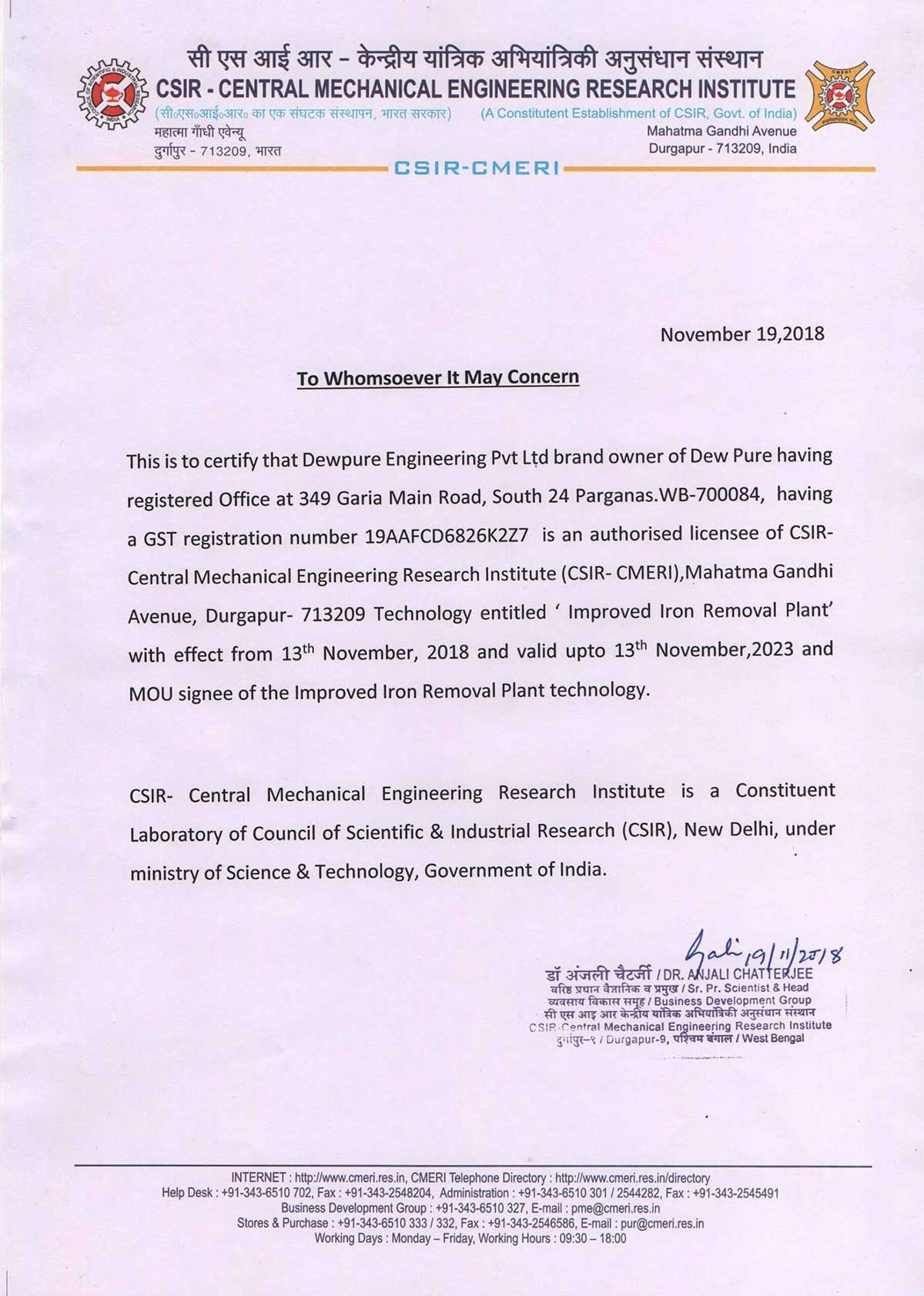

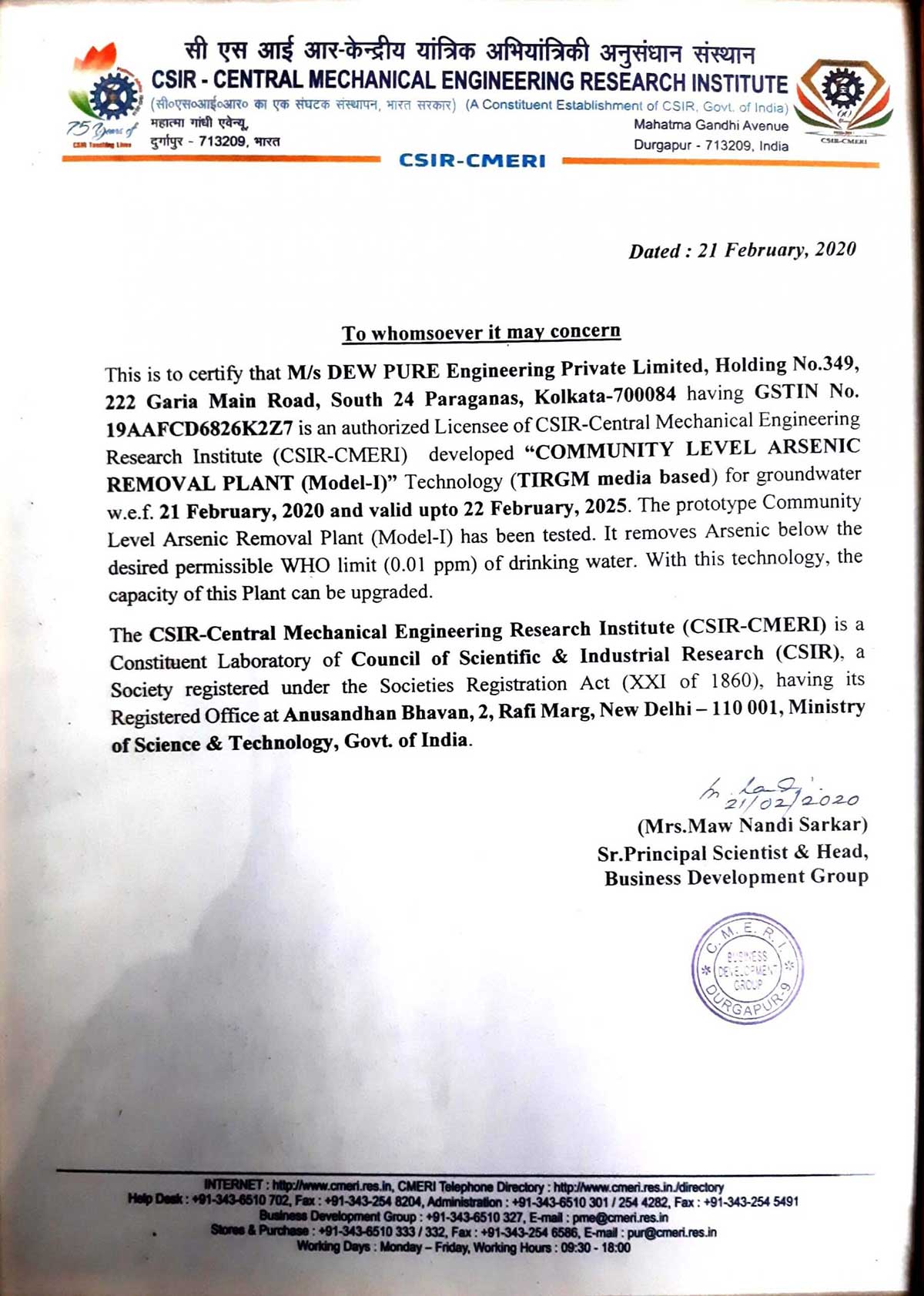

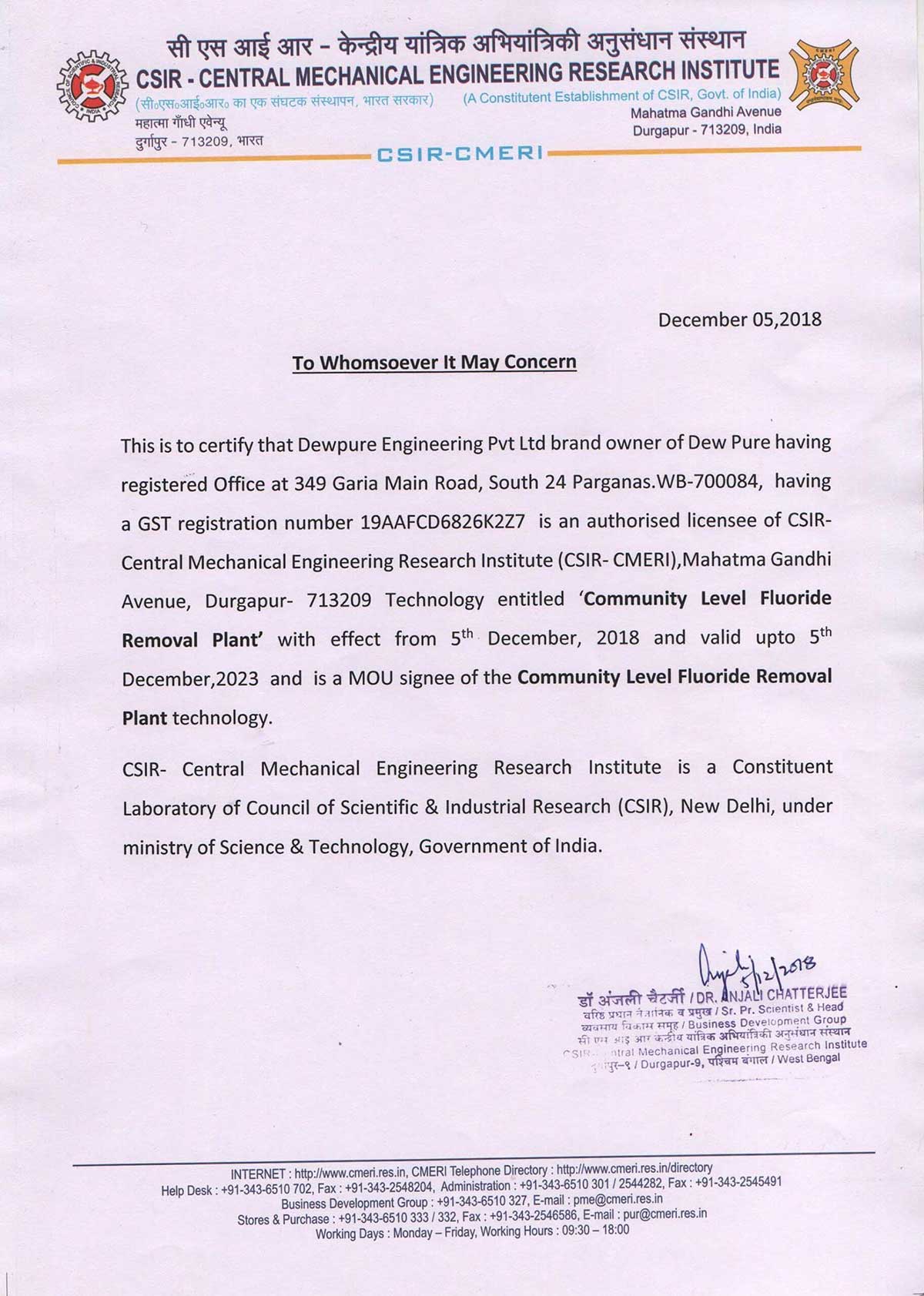

Dew Pure is the leader in manufacturing and supplying industrial and domestic RO plants that can cater to the unique needs of customers. We leverage modern innovation and high-tech upgrades to develop advanced water purifying solutions for various industries. To know more about our products, contact our experts.