Cost of RO treatment

The cost of wastewater treatments is increasing day by day. Economically the price of RO plants is lesser than the same. Hence, it is better to use RO plants instead of Wastewater treatments and save some money. Moreover, various stages in an RO plant reduce the wastewater to the minimum possible amount. Hence it is cost-effective.

Type of RO membrane feasibility

In every RO filtration plant, Cellulose Acetate and Polyamide Composite membranes are present. They have good physical as well as chemical resistance power. Out of these two membranes, the CA membrane has the feature of operating at high temperatures. Moreover, you’ll find an ample amount of chlorine residual in municipal water. Hence the CA membrane can effectively take out the chlorine from water.

Non-micro biological organic fouling

Again, nonmicrobiological fouling also plays an important role in every RO purifier. To prevent nonmicrobiological organic fouling, COD within the water is controlled. Proper use of the COD helps in the removal of the same in the long run.

Microbiological organic fouling

The effect of microbiological fouling is negative on RO systems. It reduces the effectiveness of the RO system. Thus, this is an important factor that needs to be considered. The microbiological content is thus reduced to some extent using a biocide, and then the rest can be successfully controlled by the RO purifiers.

Scaling process of RO membranes

The continuous purification process leads to the building up of scales in the RO system. This is generally prevented with the help of 3 in-built scaling systems in the RO membranes, namely Feeding acid, softener and antiscalant. Among these three, the feeding acid is considered highly important as it controls the pH level of the water.

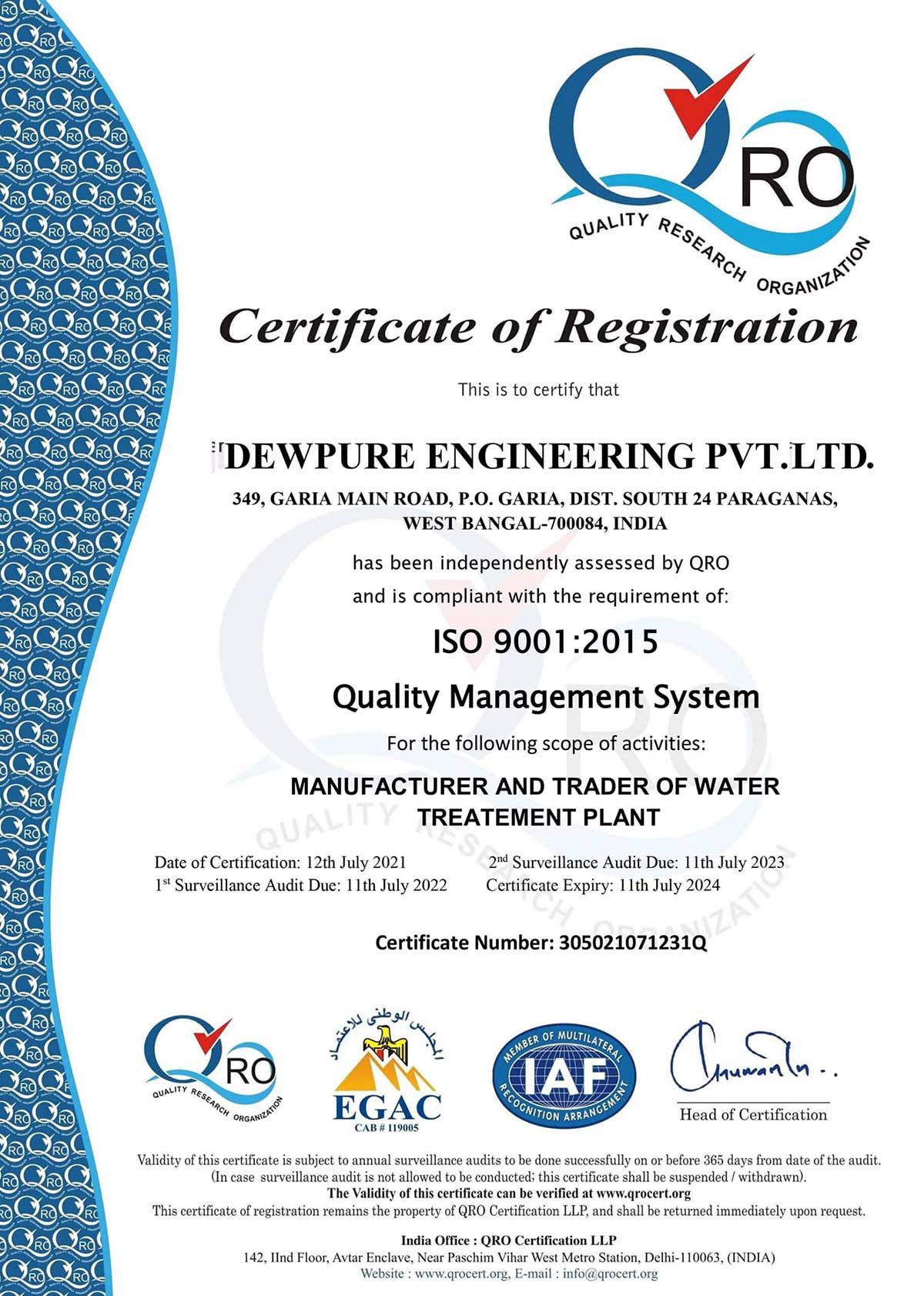

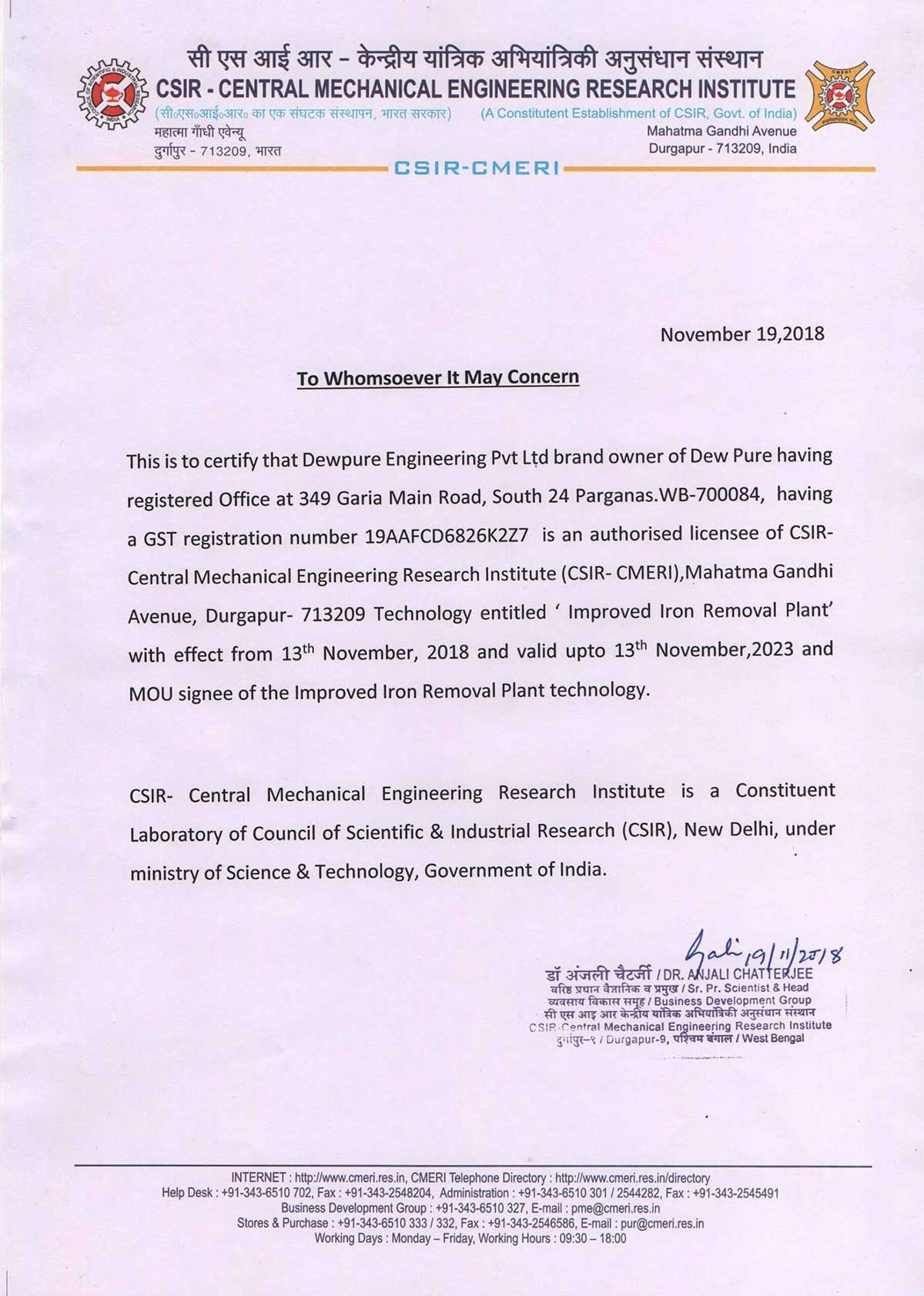

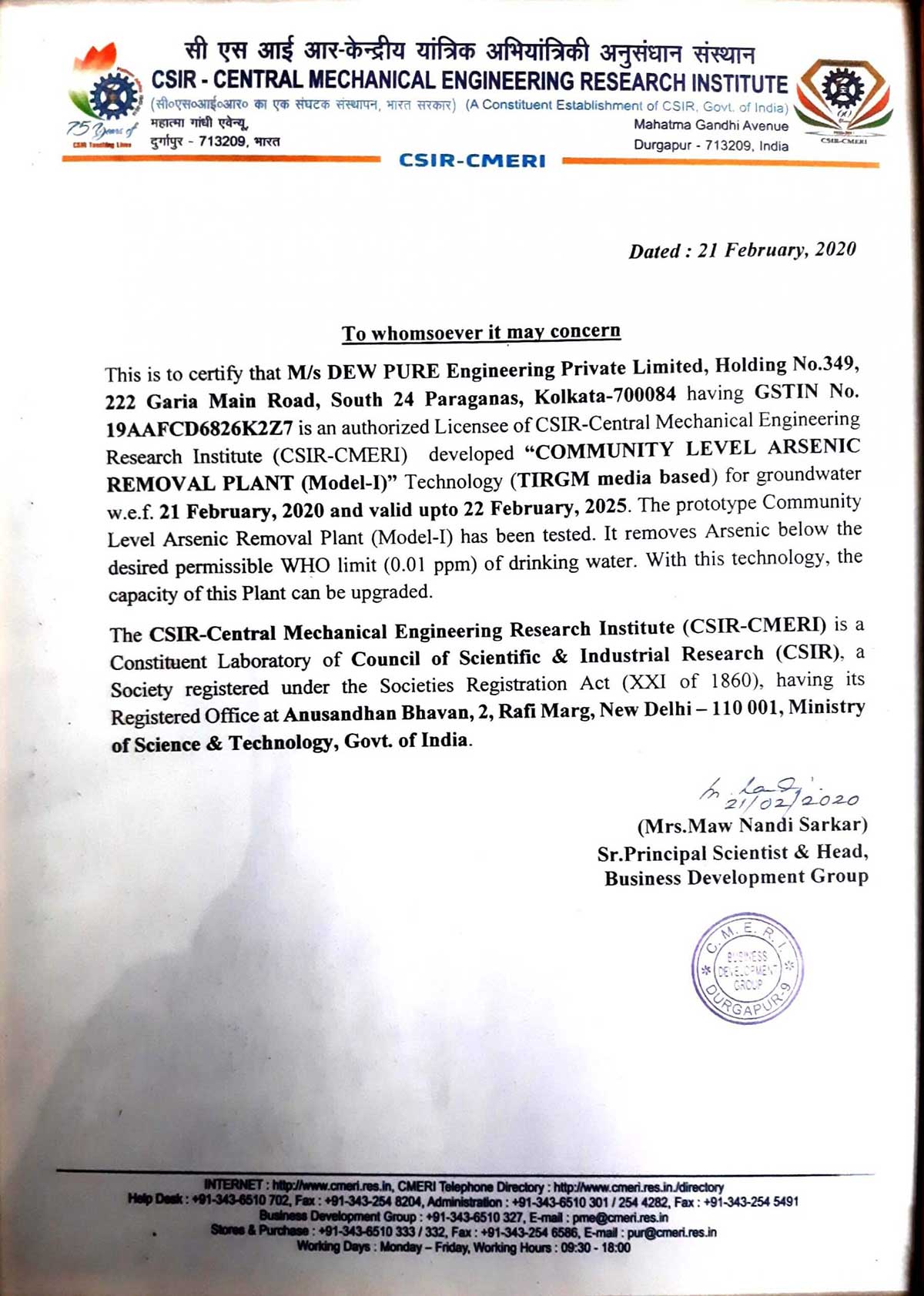

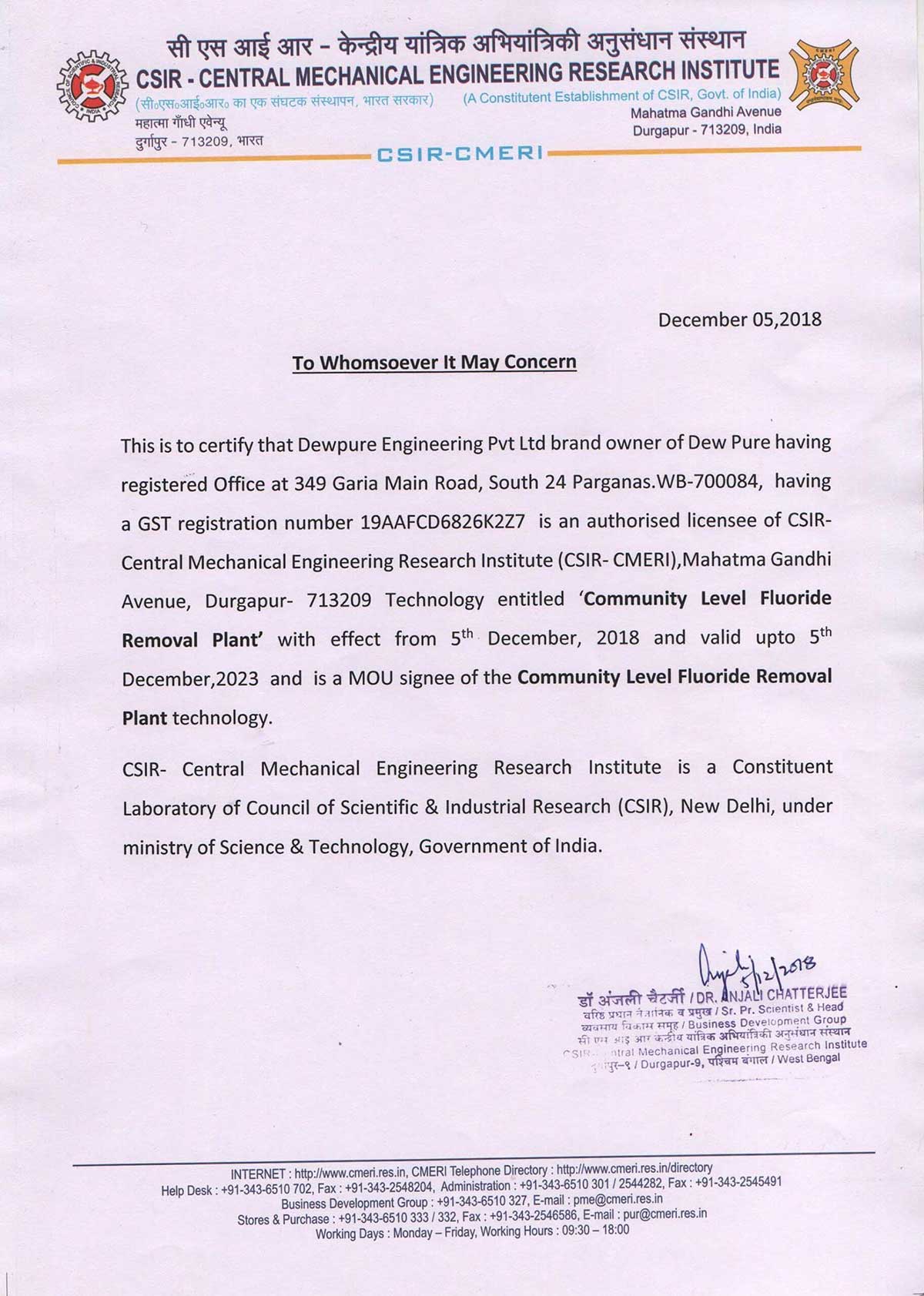

Dew Pure Mineral Water Plant Manufacturer is a renowned name in the field of water management. Our dedicated team continuously strives to deliver RO purified water treatment solutions. You’ll get safe and pure forms of water from us.