About Bottle Filling Machines

Across the world, bottled water is one of the most preferred consumable liquids. The shift to flexible packaging has further increased its demand worldwide. The bottle filling machines are available in automatic and semiautomatic versions. Most companies also use custom filling and packaging systems to bring efficiency in operation.

Benefits of Using Bottle Filling Machines

Below, we have mentioned are four advantages of using bottle filling machines.

Production consistency

Filling all containers by hand is time-consuming. It can cause inconsistencies when deciding how much water goes inside the bottle. Bottling requires extreme precision as the liquid should not come to the brim. Otherwise, it will cause spillage and damage while shipping the products.

The bottle filling machines ensure that every bottle is filled with the same amount of liquid. It causes minimal or no errors. The machines work in cycles where the workers dispense every bottle based on weight, volume, level and other measurements.

Higher production speed

The bottle filling machinery can fill several bottled containers at one time. When compared to hand-filling, the process is highly efficient. The machines are in-built with features to fill multiple bottles at once. The speed depends on the machinery fill heads and liquid viscosity. On average, these machines can fill approximately 120 bottles every minute. This way, the company can finish thousands of bottles every day.

Long term use

Industrial bottle filling machines last for a long duration. The manufacturers build them in a way that it functions without wearing. It ensures consistency in production without disruption.

You should do monthly maintenance of the bottle filling machinery. These timely checks will help you save additional expenses and effort.

Scalability

If your company’s production unit sees a surging business demand, you should upgrade the bottle filling machines. Most industrial machines come with four to six filling heads. You can add more features to it over time. Some machines can accommodate close to 16 filling heads. In the long run, this upgrade will prove useful to the business.

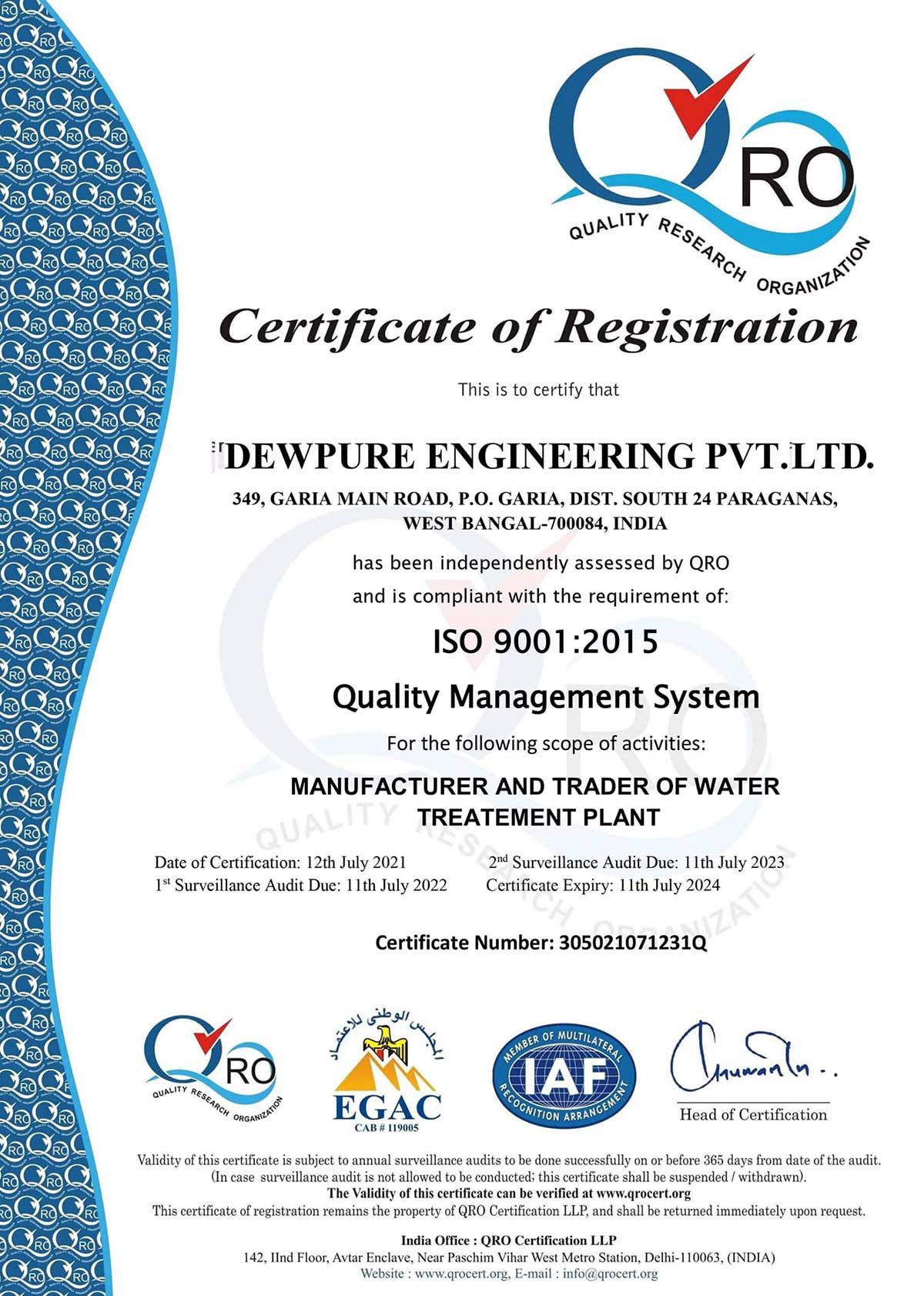

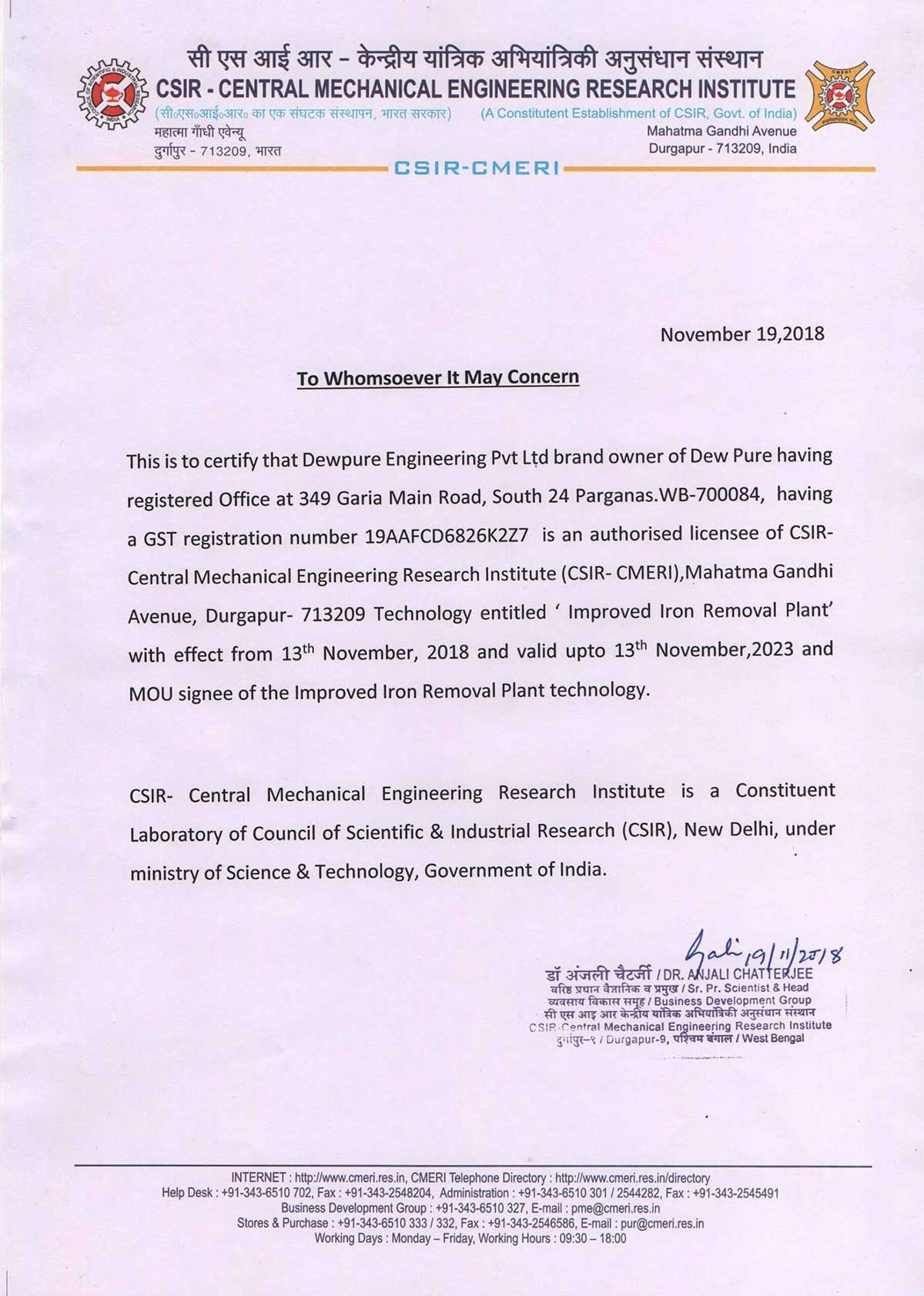

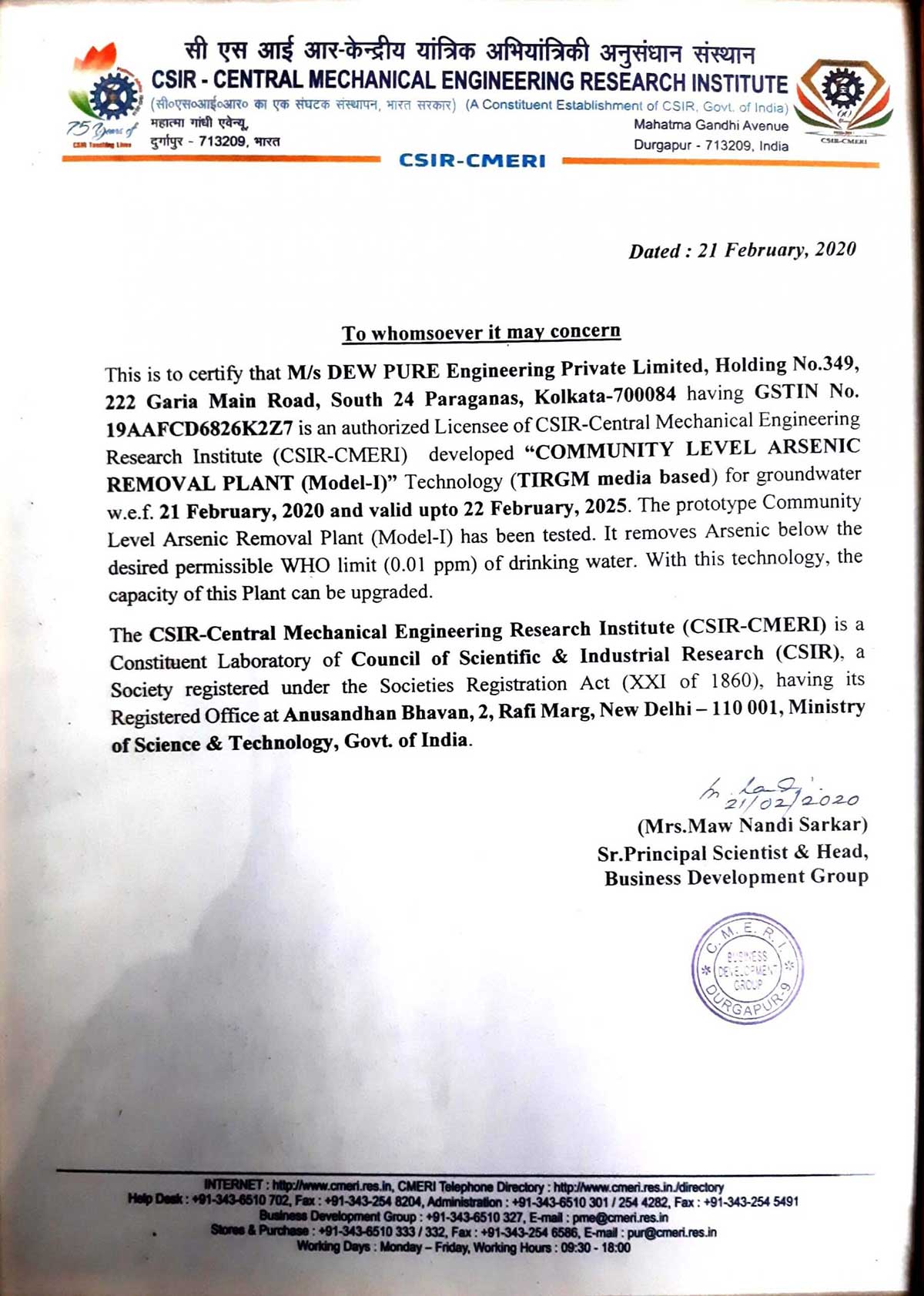

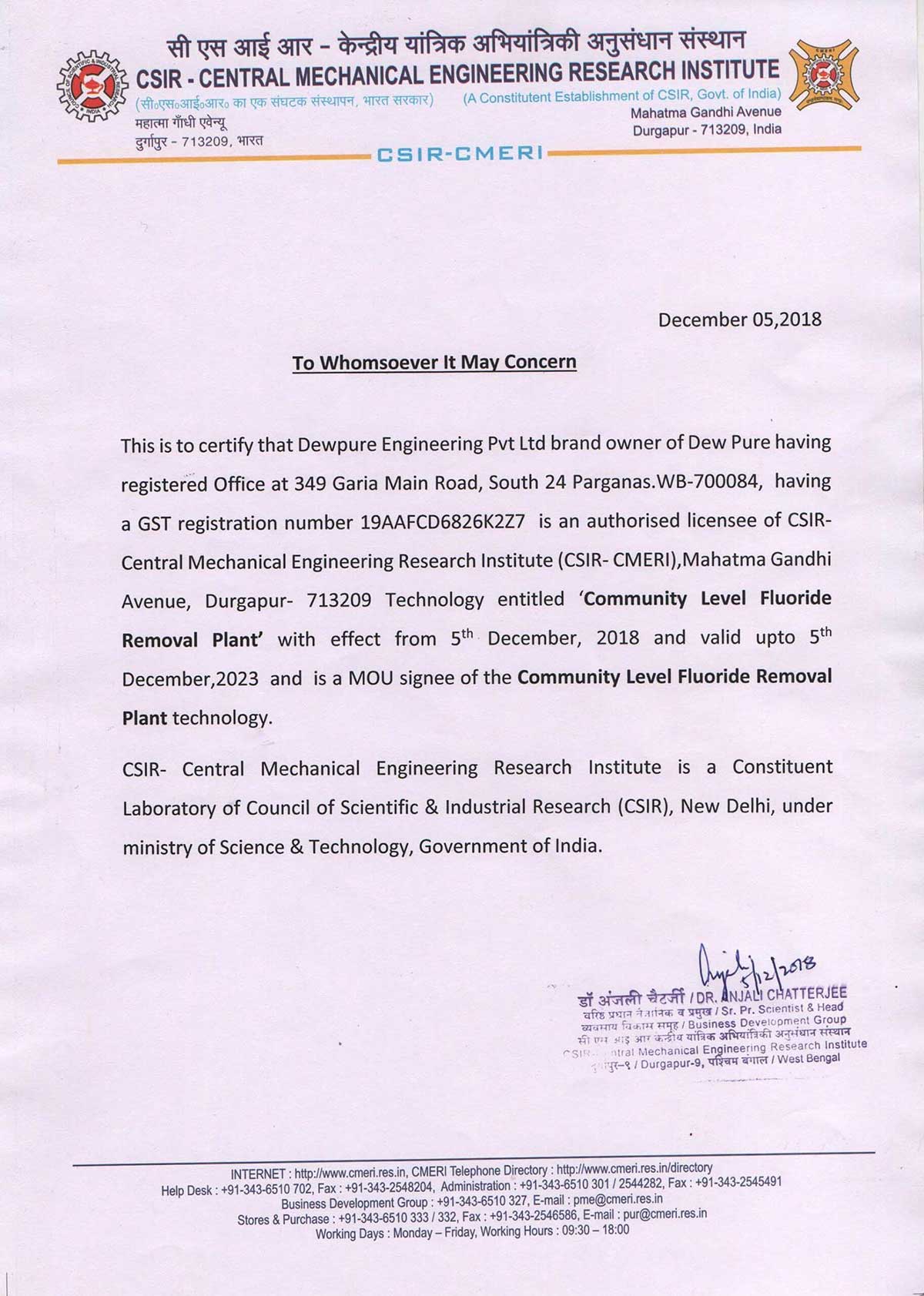

Investing in bottle filling machinery can seem like a costly affair. However, it will help your business projects scale. They help organize your assembling line and fill bottles faster. Dewpure Engineering Private Limited sell advanced bottle filling machines at competitive prices. Get in touch with the experts to know more.